A tour of the Lectrosonics factory

Lectrosonics is a very high end professional audio company known for their wireless microphones. They sell high quality, high reliability equipment for use in areas where failure is costly. The audio is delivered and mixed in real time, accurate to the millisecond.

The movie industry is one of their larger customers. Lectrosonics equipment supports synchronization using film industry standards so that the audio recorded during a shoot is in perfect sync with the video. Another interesting group of customers are courthouses and legislators. The hourly cost of a court or legislative session is high, and the cost of a mic cutting out is correspondingly high.

I met the Lectrosonics CEO, Mr. Gordon Moore, at the New Mexico Tech (NMT) Inventors and Entrepreneurs Workshop; he also graduated from NMT. I was discussing NMT's very outdated student-accessible machining equipment. An attendee pointed me to Mr. Moore, suggesting that he might have surplus machines that could be donated. As expected, he did not. Such machines are very expensive and businesses seldom maintain their profitability by giving away valuable equipment. However, he was happy to provide student tours of the Lectrosoincs factory. Note that the Lectrosonics video tour may be superior way to see the factory.

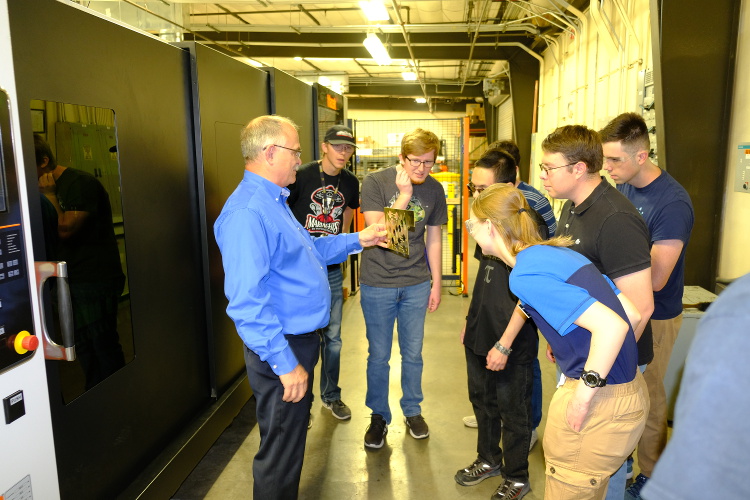

This online tour combines my two tours of Lectrosonics in March and May 2018. On the first tour a scheduling mix-up on my part resulted in the tour happening during New Mexico Tech's (NMT) spring break. While no other students could make it, Mr. Moore kindly gave me a tour. The second tour went smoothly. A large number of EE students, a technical writing student, and I, all made it.

The NMT students really enjoyed the tour, and were a bit too distracted for a good group photo!

In the main office there is a product history shelf, displaying many of the products Lectrosonics has made over the years. The newspaper (magazine?) clipping appears to be an original printing of this article, about Mark Whellman, the first paraplegic to ascend El Capitan. The Lectrosonics microphone he took with him, now sitting next to the article, withstood being dragged along the rock face throughout the climb. While the ascent was a far greater feat, Lectrosonics is rightly proud of their product taking the beating.

Engineering office

Our first stop was the engineering offices. It was immediately apparent that Lectrosonics is an engineering firm dedicated to making high quality products. Shown here is one of their work areas, fully outfitted with all the equipment necessary for an engineer to develop new products.

An electrical engineer in his natural habitat. If you are trying to create habitat for your own electrical engineer, the Ineptitude demotivational poster may no longer be available. Try luring them in with a 110GHz oscilloscope. Lacking the budget for that, you could try a Mistakes demotivator and new Picoscope, or maybe a used Tektronix.

Another part of the Radio frequency (RF) design and testing is the use of a screen room, properly called a Faraday cage. These are similar to those at NRAO. Unlike NRAO, these cages are used to protect the test from exterior interference, where NRAO mostly uses the cages to prevent computers from interfering with the surrounding telescope (though NRAO also uses some for RF testing).

As will be seen throughout this tour, Lectrosonics keeps most of their business on site. This includes a print shop. We almost lost our technical writing student, who wanted to move right in and live there.

Many of Lectrosonics products are machined out of solid aluminum, decreasing the number of fasteners and seams in the final product. While costly, this provides a superior finished product. The bars and sheets shown here will be cut and machined in the show we are touring. If you look closely (click to zoom), some of the bars were custom extruded for a specific product. This extrusion is one of the few manufacturing steps not done in house, but the cost saved is undoubtedly worth it.

Aluminum billets

Shown here are aluminum billets waiting to be machined. Once machined the parts will be coated, etched, and sent to assembly. The aluminum removed from the blocks is recycled.

Mori NTX 1000

The NTX 1000 is a direct drive CNC turn and mill machine, combining both a metalworking lathe and mill. It is used for "lights-out" machining in which material is automatically fed & machined. Finished parts are stored for later retrieval. Some interesting videos of similar machines in action can be found with a video search for NTX 1000.

Some of the metalworking tools used by the machines. These tools vary, but are often made out of tool steel and can cut aluminum, soft steels, plastic, and many other materials. Other materials are also used, especially when machining harder materials. Many machines, such as the above MORI NTX 1000, have a spindle with a large number of these tools and can automatically switch between them.

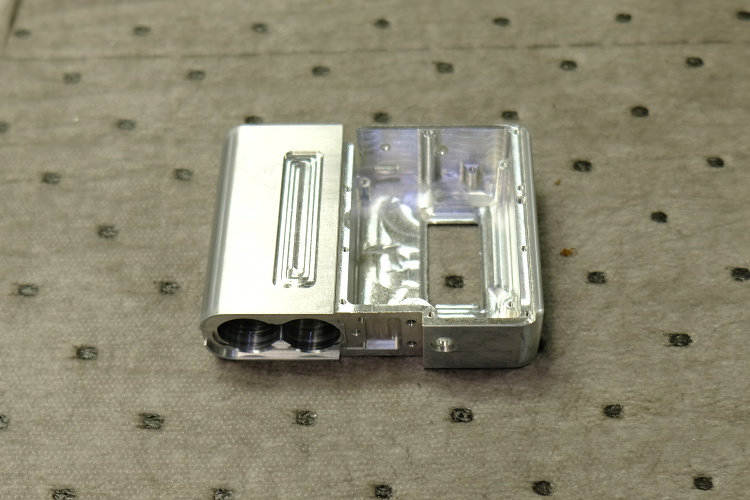

After going through several of the machines, an aluminum housing is well on its way to being completed.

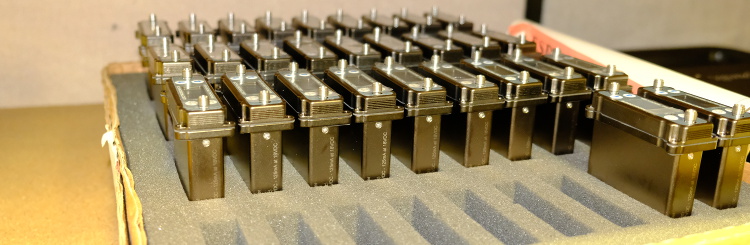

Parts are obviously manufactured in large batches.

Four drill presses on one bench! I am curious why they have so many one place, but I did not think to ask while I was there. My best guess is that each one is setup for a specific operation, and they save time by not having to re-setup quite so often.

While the vast majority of the work is done on the CNC machines, they do have a few manual ones around. These old Bridgeports last forever, though people debate how much that is due to their quality vs their not receiving the nearly non-stop use modern machines receive. I don't take sides in this debate, and just want access to a machine shop.

Machined parts are tumbled to provide the proper surface for powder coating. Shown here is some of the tumbling media.

Laser cutting

On the left is a 2kW Mazak laser cutter which can cut various metals including aluminum and stainless steel. Stainless sheet is cut out to make belt clips. The laser makes a clean enough cut that deburing is unnecessary, saving time and money. After cutting, the sheet is bent into the final shape.

This scrap was left over from cutting out samples to demonstrate the laser cutter's capability. Note the fine edges and lack of any imperfection.

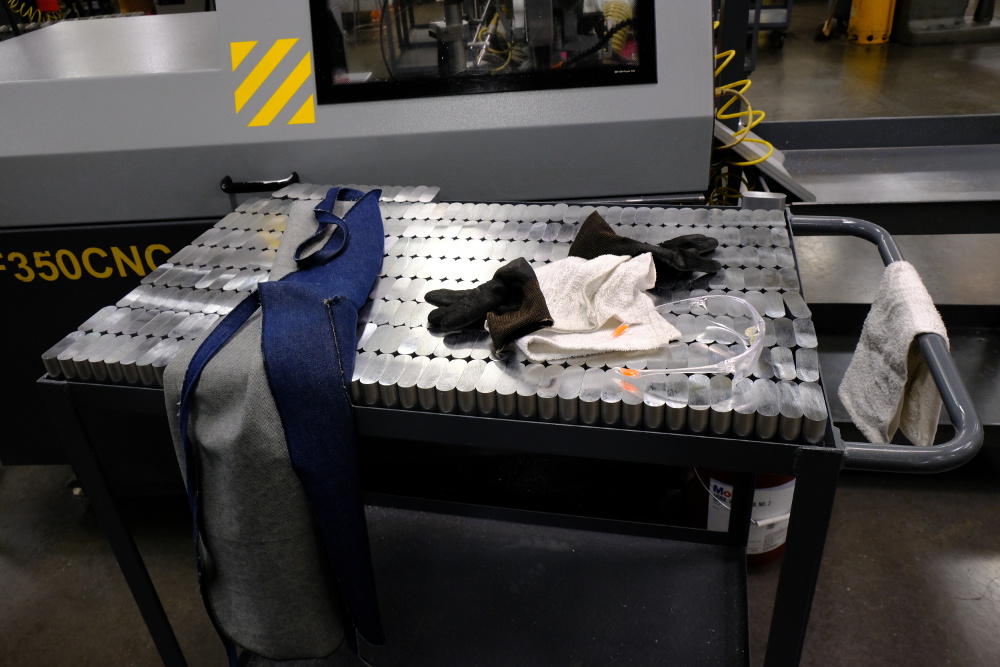

The feed table for the 2kW Mazak. Note the yellow chain and strip on the floor. There is a safety fence which automatically turns off the laser cutter if somebody comes too close while the feed table is moving.

In the foreground is the feed table for the Mazak. In the background is more of the Lectrosonics machine shop.

Laser engraving

Powder coated aluminum parts are engraved using a smaller laser cutter. The laser precisely burns through the coating, exposing the aluminum below. The result is a clean, good looking, etched product which will withstand the harsh use and abuse that Lectrosonics products are expected to endure. This is one of the many details involved in creating a high quality product.

Aligning the item you are engraving with the cutter bed is essential. The jig seen here holds the parts in place and allows for quickly swapping in the next batch for engraving.

Parts storage

A large number of parts, both mechanical and electrical, are neatly organized and stored. Many parts are needed for the ongoing assembly of new products while others are on hand for repair work.

Pick and place machine

Like the vast majority of modern electronics, Lectrosonics new products are built with surface mount components using reflow soldering. Blank circuit boards are manufactured according to Lectrosonics designs. Solder paste is placed on the board using a mask and screening process. Pick and place machines take components from reels and place them on the blank circuit board. The boards are then run through a reflow oven, melting the solder. Interestingly, components are done on both sides at the same time, and the liquid solder is able to prevent the components on the underside from falling off!

Solder techs

While a large part of the process is automated, there are solder techs to do hand soldering where needed. Some components, such as BGAs, cannot be soldered by hand. But for many components, the work done by a professional solder tech can be every bit as good, if not better, than the work done by a machine.

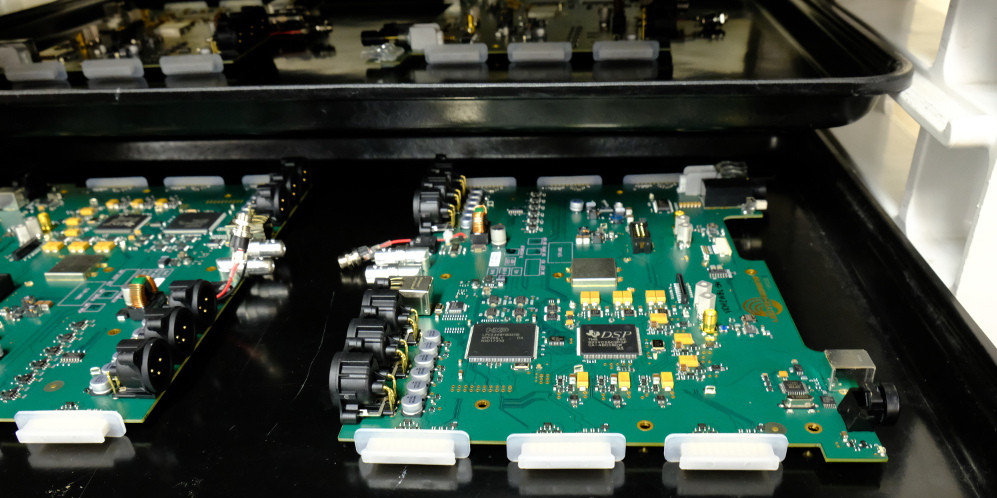

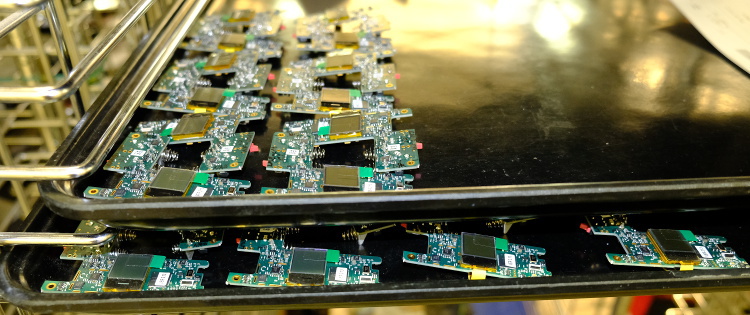

Trays of components are then delivered to technicians for testing and assembly.

There were large numbers of well-organized components in every direction!

The testing, assembly, and repair area are distinct parts of the Lectrosonics facility with their own distinct jobs. The workflow is well organized, with parts flowing smoothly through manufacturing, testing, assembly, shipping, repair, etc. However, these areas are easily confused on the tour. And, for the proposes of this online tour, a distinction is not needed.

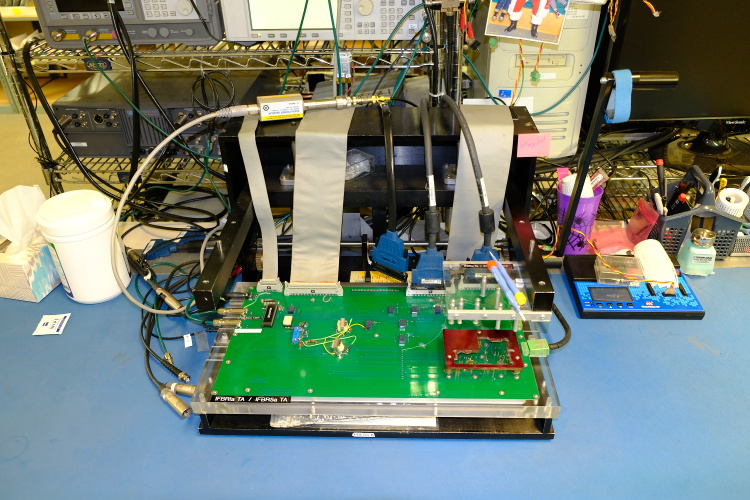

This test fixture connects to the diagnostic ports on a circuit board. It is interfaced with diagnostic equipment and a computer running LabVIEW. This provides a quick and easy way to run whatever customized tests Lectrosonics has created for their products.

After final assembly the final product is ready to ship.

The laser etching discussed above can be appreciated on the finished product. However, my hasty photography does not do it justice.

The visit was both enjoyable and educational. Many thanks to Lectrosonics, and especially Gordon Moore for the tour.

Last Updated: October 2018; integrated 2nd tour & expanded page

© David C. Hunter, 2018

fb {at) dragonsdawn (dot] org